Two production sites, with three extrusion presses of 1,600 tons / 2,200 tons / 2,800 tons, make it possible to produce anodized, powder coated, machined and thermal break aluminium profiles for the most varied sectors, such as building, mechanics, solar-photovoltaic, heating, air-conditioning, up to furnishing.

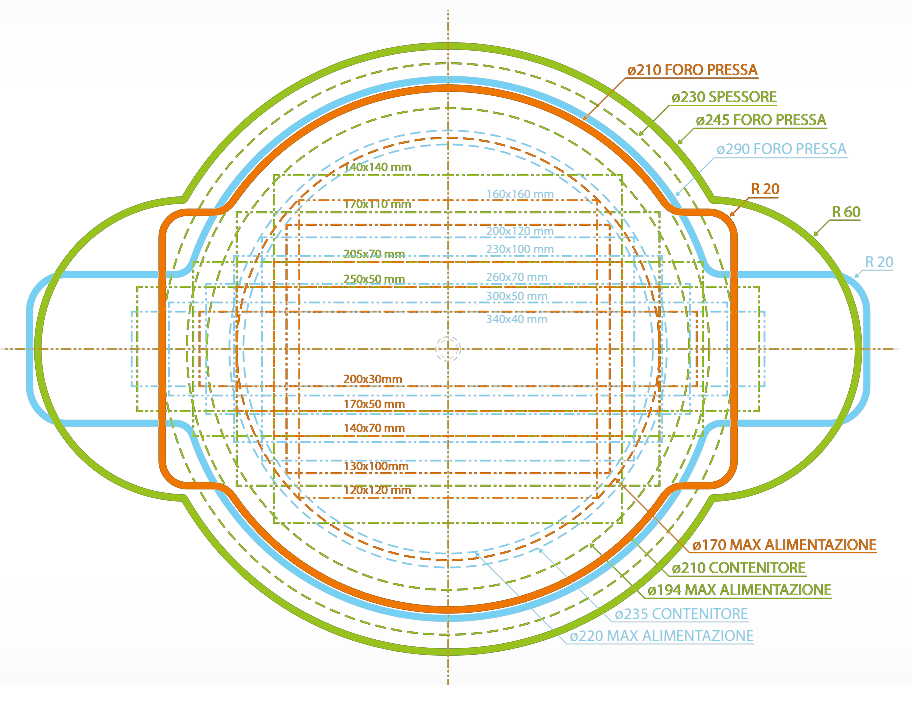

| PRESSE | 1600 t | 2200 t | 2800 t |

| MAX. EXTRUDABLE DIAMETER | 120 mm | 140 mm | 160 mm |

| MAX. PROFILE LENGTH | 8000 mm | 8200 mm | 8000 mm |

| MIN. THICKNESS | 1,2 mm | 1,4 mm | 1,5 mm |

| MAX. METRIC WEGHT | 8,0 Kg/m | 13,0 Kg/m | 18,0 Kg/m |

| ALLOYS | 6060, 6063, 6005 | 6060, 6063, 6005 | 6060, 6063, 6005, 6082 |

| HARDNESSES | TN-T6 | TN-T6 | TN-T6 |

Design with customers of the best solutions

In partnership with Phoenix International Spa, European leader in the production of matrices

Billet load, heating up to 500 ° C, billet cutting and press loading

Press capacity:

Press: 2,200 tons = 9,000 tons annually.

Presses: 1,600 tons and 2,800 tons = 16,000 tons annually

Hot stretching process of extruded rods

Heading of the rods

Preparation of the rods for the ovens

Cooking process to give aluminum better mechanical strength

Manual preparation of the profiles and automated packaging of the bundles

Logistic management of bundled bundles in our warehouses

Advanced management of shipments that comply with customer requests