APS Arosio Extrusion has a long experience producing standard and custom-designed profiles in the aluminium extrusion sector.

Based on its expertise and long experience, the company carries out a technical and feasibility analysis and offers a consultancy service to optimise the product and costs.

The high flexibility of its extrusion presses makes it possible to produce anodized, powder coated, mechanically machined and thermal-break aluminium profiles for different sectors.

In collaboration with the group's aluminium die-cast and plastic moulding partners, APS Arosio Extrusion can provide a complete project tailored to each customer.

Plant in Mariano del Friuli

Total area of 40,000 m² of which 15,000 m² is covered, a 2,200-ton press, with an annual production capacity of 9,000 tons.

Plant in Leno

Total area of 55,000 m² of which 16,500 m² is covered, two presses one of 1,600 tons and another of 2,800 tons with an annual production capacity of 16,000 tons.

Different types of alloy 6060 - 6063 - 6005 - 6082 - 5005 and the right heat treatment, allow endless possibilities to develop new ever-better quality applications for its customers, cost reductions with a high service value. All this makes APS Arosio Extrusion one of the European centres of excellence in the sector.

Thermal break assembly is the best method to counter the temperature fluctuations...

MORE INFO

The test and control activity is carried out on all production batches...

MORE INFO

The dies workshops is the APS Arosio Extrusion strategic area...

MORE INFO

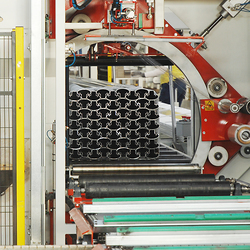

A systems of packaging fully automated...

MORE INFO

A logistics is a strategic function of APS Arosio Extrusion...

MORE INFO